Vertical separator: it is used for the application of liquid drop removal and the working condition of small floor area.

Horizontal separator: used to handle high flow rate and large liquid drop

Economical separator: it is suitable for working conditions with space limitation on space and pipeline.

Product characteristics

Non standard design

Large capacity blade

Excellent performance

ASME International Standard manufacturing

Product application

Gas transmission and metering

Fuel gas regulation

Oil mist removal

chemical plant

Ammonia and urea plant

Desiccant bed protection

Molecular sieve protection

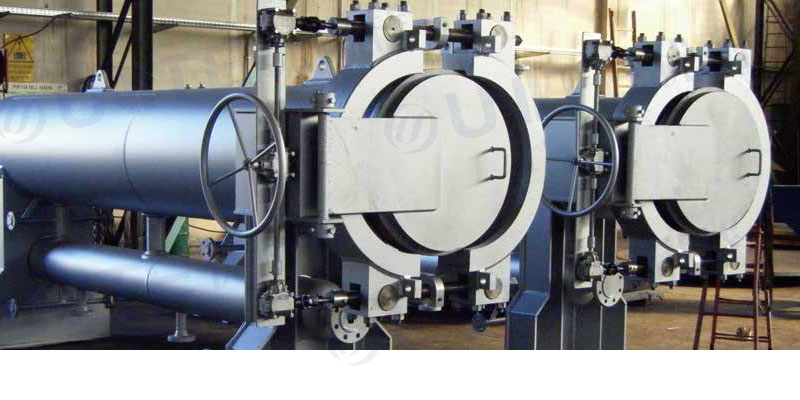

Single cylinder gas separator

Efficient liquid removal

Wide range of liquid handling operations, including droplets

Extremely high gas handling capacity

Can be customized for three-phase air flow

Enough space for pollution

Features:

These separators are designed to provide efficient liquid removal with high gas flow capacity. They can effectively deal with large liquid plugs and are easy to be used in three-phase separation.

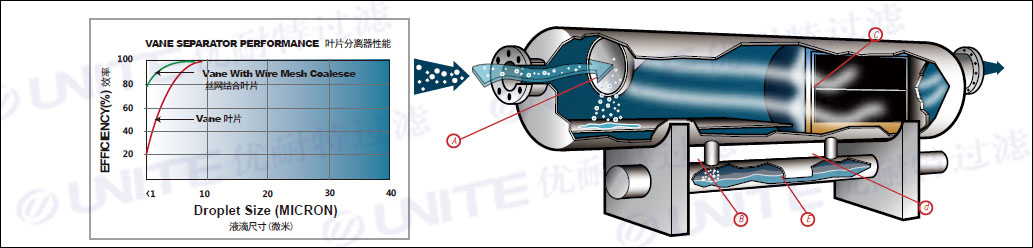

Working principle

• the gas and liquid entering the container are divided through the inlet baffle to remove large drops and free liquid.

• the liquid falls to the bottom of the container through the stilling water plate and enters the first storage tank.

• gas and remaining water mist into vane separator

• the remaining liquid collected at the bottom of the blade set is discharged by the water pipe.

• the sunken sewer and seal structure form the best drainage way.

• drain and level control to ensure proper liquid discharge from the container.

High efficiency liquid drop removal without liquid entrainment in double drum separator

Working principle

(a) the gas and liquid entering the container are separated by the inlet baffle to remove large drops and free water mist

(b) the liquid flows into the liquid storage chamber through the first lower blowdown pipe.

(c) clean gas and residual water mist enter the vane separator.

(d) the remaining liquid drops collected at the bottom of the discharge port of the vane demister enter the liquid storage chamber through the second blowdown pipe.

(E) liquid level gauge can be set in the liquid storage chamber of collecting two blowdown pipes.

Product characteristics

The double drum separator is designed to provide efficient liquid removal. In addition, they can achieve higher gas flow capacity through longitudinal arrangement. A separating element is arranged in the upper cylinder, and the lower cylinder takes away the separated liquid. The gas flows from the upper cylinder to eliminate re entrainment. In addition, the lower cylinder acts as a retention chamber, providing a residence time for the bubbles to separate from the liquid.

Vertical gas separator function

Efficient removal of liquid from air flow

Large scope of work

Effective liquid removal rate

Minimum floor area

High and low liquid: gas compatibility

Improved form for existing vertical separator

Product characteristics

Special vertical gas separator designed to handle high and low liquid to gas ratio. They are especially suitable for applications where heavy liquid entrainment causes water mist problems. Special proprietary equipment provides a smaller container configuration than mesh pads or other separation devices.

Working principle

(a) the gas and liquid entering the container are separated by the inlet baffle to remove large liquid drops and free liquid.

(b) gas and residual mist enter the vane separator.

(c) the separated droplets are collected at the bottom of the blade.

(d) submerged drains drain the liquid to the bottom of the container.

(E) the level gauge controls and monitors the amount of liquid collected in order to properly drain the liquid from the container.

unite@unitefilter.com

unite@unitefilter.com No. 24 all the way,industrial park,new area,Wuxi

No. 24 all the way,industrial park,new area,Wuxi  0510-85956566 400-668-0669

0510-85956566 400-668-0669