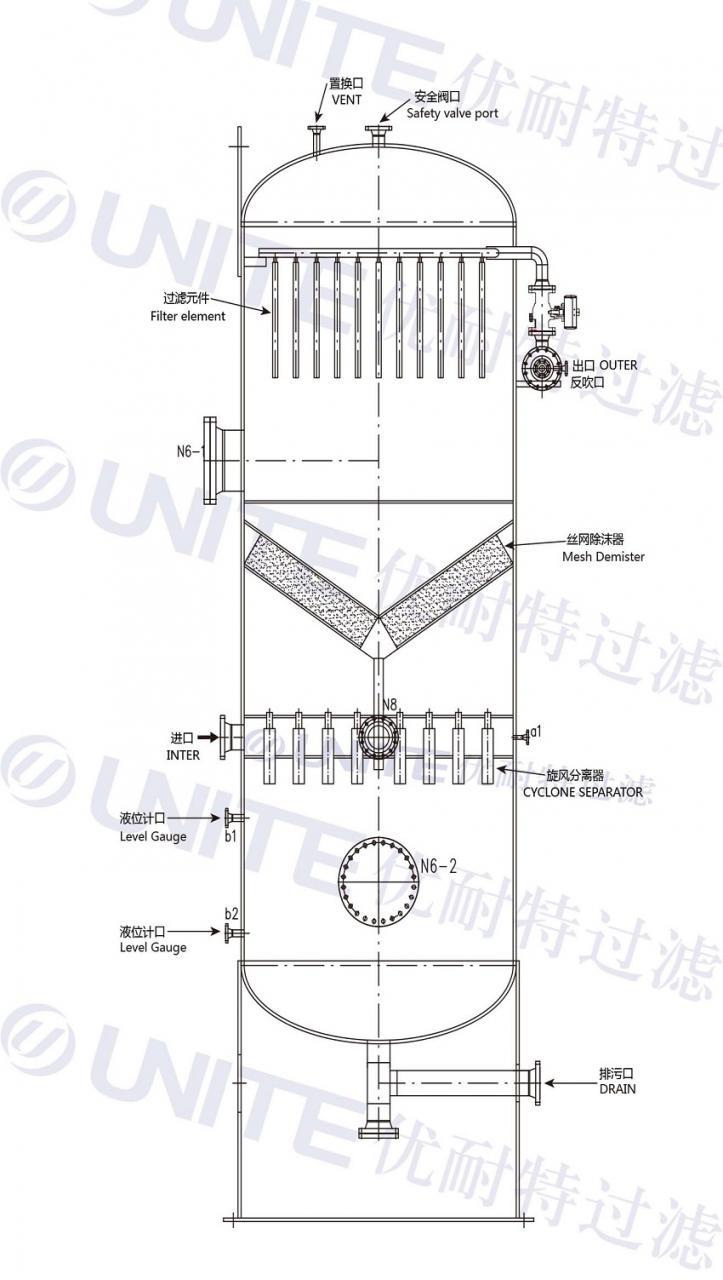

The unique coke oven gas filter adopts the three-stage mechanical separation internals structure with special improvement design and the separation mode of high-efficiency dust removal and oil removal filter element to separate and purify the coke oven gas. The equipment adopts vertical structure, and the filter element is installed by hanging type, which is convenient to separate filter cake during cleaning. The patent design of the invention includes an online back blowing cleaning device, which can realize the rapid cleaning and regeneration of the screen and the filter element.

Design features

The filter material selected for the filter element is alloy material with corrosion resistance, high temperature resistance (≤ 600 ℃), and ultra-low temperature resistance. This patent is a perfect and organic combination of two types of filter materials, surface filtration and deep filtration. The raw material liquid first reaches the outside of the filter element, and first filters the filter material through the surface layer. The dust in the liquid quickly forms a filter cake on the surface of the filter element. A small amount of dust enters into the deep filter material with the raw material liquid. After the interception of the deep filter material, the filter efficiency of the filter element is greatly improved (≥ 99.99%) to meet the very demanding requirements of users. The porosity of the patented filter element is over 85% (when the precision is 0.5 μ m). The friction coefficient of the filter material in the surface layer is very low, which is equivalent to the roughness of about 0.4. The friction coefficient determines the energy consumption and ash cleaning effect of the filter element. The filter element has good back blowing performance, and the back blowing is very simple. The filter element can be cleaned online or disassembled for ultrasonic cleaning. After cleaning, it can reach more than 95% before it is used. As long as there is no obvious damage, the filter element can be cleaned repeatedly.

Operation principle

The coke oven gas enters into the filter barrel through the tangent line of the guide device set at the inlet, and then enters the cyclones for centrifugation again after the first stage of cyclones separation. The large solid particles and liquid drops are centrifuged and separated, and then through the wire mesh, the solid particles and large liquid drops of the second stage particle size are intercepted. Finally, the gas passes through the high-efficiency dedusting and oil removing filter element from the outside to the inside, and the solid impurities are removed The quality particles and liquid drops are caught and intercepted outside the filter element, and the coke oven gas after four-stage filtration is sent out from the outlet.

With the progress of filtration, the solid particle cake layer attached to the filter element becomes thicker, and the filtration resistance of the filter element will gradually increase, so it is necessary to regenerate the filter element.

When the filter element is regenerated, first close the inlet and outlet, cut out the equipment in the system, open the blowback port, and carry out the blowback operation. The high-pressure steam is used for pulse back blowing, the filter cake is blasted and the filter element is washed, so that the filter cake layer on the surface is quickly separated from the filter material and falls off; then the back blowing port of the screen is used to back blow the screen, during the back blowing regeneration process of the equipment, the waste liquid slag deposited at the bottom of the tank body is discharged from the slag discharge port. Open the on-off valve at the drain outlet of the filter to discharge the oil and slag after the back blowing.

After a period of use (generally speaking, when the system is shut down for maintenance), the head shall be opened, the filter element shall be taken out and thoroughly cleaned. At the same time, the screen shall be maintained and cleaned, and the screen can be washed with clean water. During the cleaning process, the slag and waste water deposited at the bottom of the tank body are discharged from the slag discharge port.

The unique coke oven gas filter adopts the three-stage mechanical separation internals structure with special improvement design and the separation mode of high-efficiency dust removal and oil removal filter element to separate and purify the coke oven gas. The equipment adopts vertical structure, and the filter element is installed by hanging type, which is convenient to separate filter cake during cleaning. The patent design of the invention includes an online back blowing cleaning device, which can realize the rapid cleaning and regeneration of the screen and the filter element.

Design features

The filter material selected for the filter element is alloy material with corrosion resistance, high temperature resistance (≤ 600 ℃), and ultra-low temperature resistance. This patent is a perfect and organic combination of two types of filter materials, surface filtration and deep filtration. The raw material liquid first reaches the outside of the filter element, and first filters the filter material through the surface layer. The dust in the liquid quickly forms a filter cake on the surface of the filter element. A small amount of dust enters into the deep filter material with the raw material liquid. After the interception of the deep filter material, the filter efficiency of the filter element is greatly improved (≥ 99.99%) to meet the very demanding requirements of users. The porosity of the patented filter element is over 85% (when the precision is 0.5 μ m). The friction coefficient of the filter material in the surface layer is very low, which is equivalent to the roughness of about 0.4. The friction coefficient determines the energy consumption and ash cleaning effect of the filter element. The filter element has good back blowing performance, and the back blowing is very simple. The filter element can be cleaned online or disassembled for ultrasonic cleaning. After cleaning, it can reach more than 95% before it is used. As long as there is no obvious damage, the filter element can be cleaned repeatedly.

Operation principle

The coke oven gas enters into the filter barrel through the tangent line of the guide device set at the inlet, and then enters the cyclones for centrifugation again after the first stage of cyclones separation. The large solid particles and liquid drops are centrifuged and separated, and then through the wire mesh, the solid particles and large liquid drops of the second stage particle size are intercepted. Finally, the gas passes through the high-efficiency dedusting and oil removing filter element from the outside to the inside, and the solid impurities are removed The quality particles and liquid drops are caught and intercepted outside the filter element, and the coke oven gas after four-stage filtration is sent out from the outlet.

With the progress of filtration, the solid particle cake layer attached to the filter element becomes thicker, and the filtration resistance of the filter element will gradually increase, so it is necessary to regenerate the filter element.

When the filter element is regenerated, first close the inlet and outlet, cut out the equipment in the system, open the blowback port, and carry out the blowback operation. The high-pressure steam is used for pulse back blowing, the filter cake is blasted and the filter element is washed, so that the filter cake layer on the surface is quickly separated from the filter material and falls off; then the back blowing port of the screen is used to back blow the screen, during the back blowing regeneration process of the equipment, the waste liquid slag deposited at the bottom of the tank body is discharged from the slag discharge port. Open the on-off valve at the drain outlet of the filter to discharge the oil and slag after the back blowing.

After a period of use (generally speaking, when the system is shut down for maintenance), the head shall be opened, the filter element shall be taken out and thoroughly cleaned. At the same time, the screen shall be maintained and cleaned, and the screen can be washed with clean water. During the cleaning process, the slag and waste water deposited at the bottom of the tank body are discharged from the slag discharge port.

The unique coke oven gas filter adopts the three-stage mechanical separation internals structure with special improvement design and the separation mode of high-efficiency dust removal and oil removal filter element to separate and purify the coke oven gas. The equipment adopts vertical structure, and the filter element is installed by hanging type, which is convenient to separate filter cake during cleaning. The patent design of the invention includes an online back blowing cleaning device, which can realize the rapid cleaning and regeneration of the screen and the filter element.

Design features

The filter material selected for the filter element is alloy material with corrosion resistance, high temperature resistance (≤ 600 ℃), and ultra-low temperature resistance. This patent is a perfect and organic combination of two types of filter materials, surface filtration and deep filtration. The raw material liquid first reaches the outside of the filter element, and first filters the filter material through the surface layer. The dust in the liquid quickly forms a filter cake on the surface of the filter element. A small amount of dust enters into the deep filter material with the raw material liquid. After the interception of the deep filter material, the filter efficiency of the filter element is greatly improved (≥ 99.99%) to meet the very demanding requirements of users. The porosity of the patented filter element is over 85% (when the precision is 0.5 μ m). The friction coefficient of the filter material in the surface layer is very low, which is equivalent to the roughness of about 0.4. The friction coefficient determines the energy consumption and ash cleaning effect of the filter element. The filter element has good back blowing performance, and the back blowing is very simple. The filter element can be cleaned online or disassembled for ultrasonic cleaning. After cleaning, it can reach more than 95% before it is used. As long as there is no obvious damage, the filter element can be cleaned repeatedly.

Operation principle

The coke oven gas enters into the filter barrel through the tangent line of the guide device set at the inlet, and then enters the cyclones for centrifugation again after the first stage of cyclones separation. The large solid particles and liquid drops are centrifuged and separated, and then through the wire mesh, the solid particles and large liquid drops of the second stage particle size are intercepted. Finally, the gas passes through the high-efficiency dedusting and oil removing filter element from the outside to the inside, and the solid impurities are removed The quality particles and liquid drops are caught and intercepted outside the filter element, and the coke oven gas after four-stage filtration is sent out from the outlet.

With the progress of filtration, the solid particle cake layer attached to the filter element becomes thicker, and the filtration resistance of the filter element will gradually increase, so it is necessary to regenerate the filter element.

When the filter element is regenerated, first close the inlet and outlet, cut out the equipment in the system, open the blowback port, and carry out the blowback operation. The high-pressure steam is used for pulse back blowing, the filter cake is blasted and the filter element is washed, so that the filter cake layer on the surface is quickly separated from the filter material and falls off; then the back blowing port of the screen is used to back blow the screen, during the back blowing regeneration process of the equipment, the waste liquid slag deposited at the bottom of the tank body is discharged from the slag discharge port. Open the on-off valve at the drain outlet of the filter to discharge the oil and slag after the back blowing.

After a period of use (generally speaking, when the system is shut down for maintenance), the head shall be opened, the filter element shall be taken out and thoroughly cleaned. At the same time, the screen shall be maintained and cleaned, and the screen can be washed with clean water. During the cleaning process, the slag and waste water deposited at the bottom of the tank body are discharged from the slag discharge port.

unite@unitefilter.com

unite@unitefilter.com No. 24 all the way,industrial park,new area,Wuxi

No. 24 all the way,industrial park,new area,Wuxi  0510-85956566 400-668-0669

0510-85956566 400-668-0669