- Product Description

- Design Parameters

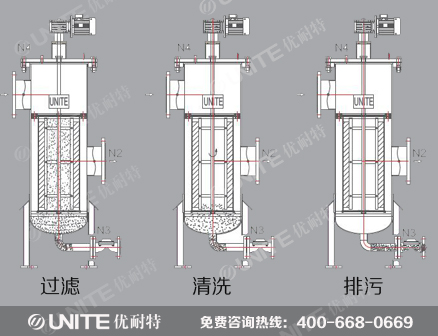

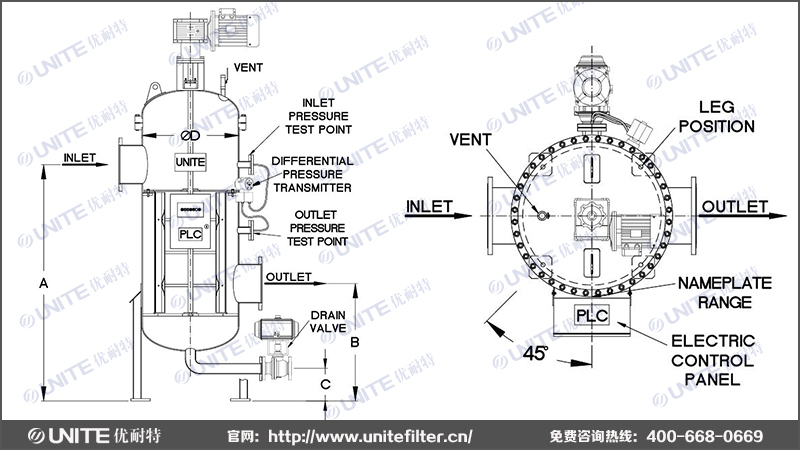

working principle:

The liquid flows in from the inlet and flows out from the inner surface of the filter element. The lower end of the filter element is connected with the outlet. The liquid flows out from the outlet and the impurity particles are intercepted on the inner surface of the filter element. When a certain amount of impurity is intercepted on the surface of the filter element, the cleaning procedure is started at a fixed time or according to the set differential pressure. The speed reducer / cylinder drives the scraper blade attached to the surface of the filter element to rotate and scrape off the impurities and impurities on the inner surface of the filter element The scraper leaves the filter element surface, and the liquid falls into the bottom of the filter along with the downward flow. The rotary sweep plate sweeps the heavy impurities at the bottom into the dirt accumulation chamber, where the impurities accumulate in the dirt accumulation chamber and the bottom of the filter. The drain valve is opened regularly to discharge the liquid with high concentration from the drain outlet, which can be recycled.

Technical features and advantages:

1. Fully automatic operation, 24-hour continuous on-line filtration, ending heavy filter element replacement and cleaning;

2. The concentration of waste impurities is high, and it can be recycled to reduce the loss of high-value materials;

3. Closed filtration to prevent leakage of hazardous materials, which is conducive to safety production and employee health;

4. Various advanced control systems are optional, with high efficiency, high reliability and long service life;

5. The filtration pressure loss is small, the flow rate is stable, which is conducive to the continuous and stable process;

6. Small floor area, saving consumables cost and environmental protection treatment cost;

7. The backwash function can be added to assist in cleaning the filter element;

8. The standard upper end cover auxiliary lifting device can open and close the filter easily;

9. Adopt metal sheet scraper / tetrafluorocarbon scraper, with excellent scraping effect, significantly improve the ability of impurity removal, and avoid crushing impurities;

10. Under the operation condition with certain viscosity medium, the motor can be replaced with air cylinder to avoid motor locking and make the operation more stable.

working principle:

The liquid flows in from the inlet and flows out from the inner surface of the filter element. The lower end of the filter element is connected with the outlet. The liquid flows out from the outlet and the impurity particles are intercepted on the inner surface of the filter element. When a certain amount of impurity is intercepted on the surface of the filter element, the cleaning procedure is started at a fixed time or according to the set differential pressure. The speed reducer / cylinder drives the scraper blade attached to the surface of the filter element to rotate and scrape off the impurities and impurities on the inner surface of the filter element The scraper leaves the filter element surface, and the liquid falls into the bottom of the filter along with the downward flow. The rotary sweep plate sweeps the heavy impurities at the bottom into the dirt accumulation chamber, where the impurities accumulate in the dirt accumulation chamber and the bottom of the filter. The drain valve is opened regularly to discharge the liquid with high concentration from the drain outlet, which can be recycled.

Technical features and advantages:

1. Fully automatic operation, 24-hour continuous on-line filtration, ending heavy filter element replacement and cleaning;

2. The concentration of waste impurities is high, and it can be recycled to reduce the loss of high-value materials;

3. Closed filtration to prevent leakage of hazardous materials, which is conducive to safety production and employee health;

4. Various advanced control systems are optional, with high efficiency, high reliability and long service life;

5. The filtration pressure loss is small, the flow rate is stable, which is conducive to the continuous and stable process;

6. Small floor area, saving consumables cost and environmental protection treatment cost;

7. The backwash function can be added to assist in cleaning the filter element;

8. The standard upper end cover auxiliary lifting device can open and close the filter easily;

9. Adopt metal sheet scraper / tetrafluorocarbon scraper, with excellent scraping effect, significantly improve the ability of impurity removal, and avoid crushing impurities;

10. Under the operation condition with certain viscosity medium, the motor can be replaced with air cylinder to avoid motor locking and make the operation more stable.

Application fields:

▲ polymer ▲ coating

▲ adhesive ▲ plastisol

Latex coating

▲ ink ▲ lubricant

▲Peanut butter

Application fields:

▲ polymer ▲ coating

▲ adhesive ▲ plastisol

Latex coating

▲ ink ▲ lubricant

▲Peanut butter

|

产品型号 |

近似尺寸(英寸) |

管口尺寸(英寸) |

参考流量 |

|

A B C D |

Inlet/Outlet Drain |

m3/h |

|

|

G1-219 |

38 18 8 8 |

2” 1” |

30 |

|

G1-350 |

41 21 8 14 |

3” 1” |

50 |

|

G1-450 |

49 25 9 18 |

5” 2” |

100 |

|

G1-550 |

51 27 9 22 |

6” 2” |

125 |

|

G1-650 |

54 29 9 26 |

8” 2” |

150 |

|

G1-750 |

57 31 9 30 |

10” 2” |

200 |

unite@unitefilter.com

unite@unitefilter.com No. 24 all the way,industrial park,new area,Wuxi

No. 24 all the way,industrial park,new area,Wuxi  0510-85956566 400-668-0669

0510-85956566 400-668-0669