- Product Description

- Design Parameters

The u-zc-xd1 / xd2 high efficiency backwash self-cleaning filter is suitable for the filtration of particulate impurities with high flow, high speed and low viscosity.

The high-efficiency backwash self-cleaning filter is a mechanical and electrical integration product, which has the advantages of reasonable design, high filtration efficiency, low operation cost and continuous filtration in the backwash process. It is widely used in metallurgy, chemical industry, electric power, oilfield reinjection water, ship ballast water, sea water utilization, environmental protection water treatment and other fields.

Design features of high efficiency backwash self cleaning filter:

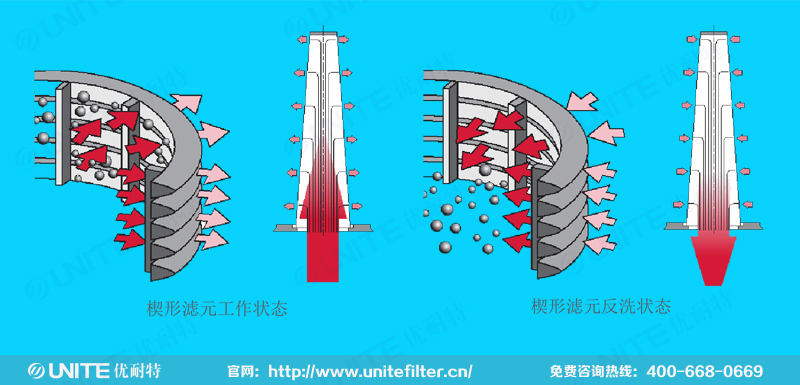

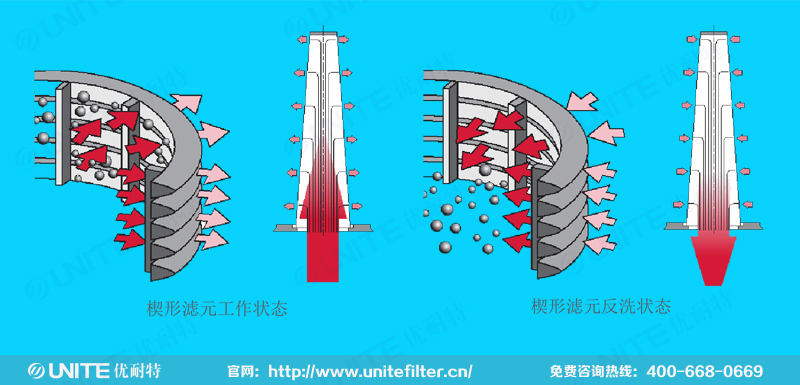

1. Adopt the internal mechanical structure of patented technology to realize the real backwash function;

2. Thoroughly remove the impurities retained by the filter screen, clean it without dead angle, pass through without attenuation, and ensure the filtering efficiency and long service life;

3. The filter equipment has compact and reasonable structure design, small floor area, flexible and convenient installation and movement;

Design features of high efficiency backwash self cleaning filter:

1. Adopt the internal mechanical structure of patented technology to realize the real backwash function;

2. Thoroughly remove the impurities retained by the filter screen, clean it without dead angle, pass through without attenuation, and ensure the filtering efficiency and long service life;

3. The filter equipment has compact and reasonable structure design, small floor area, flexible and convenient installation and movement;

Design features of high efficiency backwash self cleaning filter:

1. Adopt the internal mechanical structure of patented technology to realize the real backwash function;

2. Thoroughly remove the impurities retained by the filter screen, clean it without dead angle, pass through without attenuation, and ensure the filtering efficiency and long service life;

3. The filter equipment has compact and reasonable structure design, small floor area, flexible and convenient installation and movement;

Design features of high efficiency backwash self cleaning filter:

1. Adopt the internal mechanical structure of patented technology to realize the real backwash function;

2. Thoroughly remove the impurities retained by the filter screen, clean it without dead angle, pass through without attenuation, and ensure the filtering efficiency and long service life;

3. The filter equipment has compact and reasonable structure design, small floor area, flexible and convenient installation and movement;

Working principle diagram of filter element:

4. The filtering equipment is made of 304, 316L, 2205, Monel and other materials, with wedge-shaped filter screen, which has high strength, high precision and corrosion resistance, and the maximum filtering accuracy can reach 25 microns;

5. The filtering equipment can realize automatic backwashing through its own retrieval and strain function, which can cope with unstable water quality fluctuation without manual intervention;

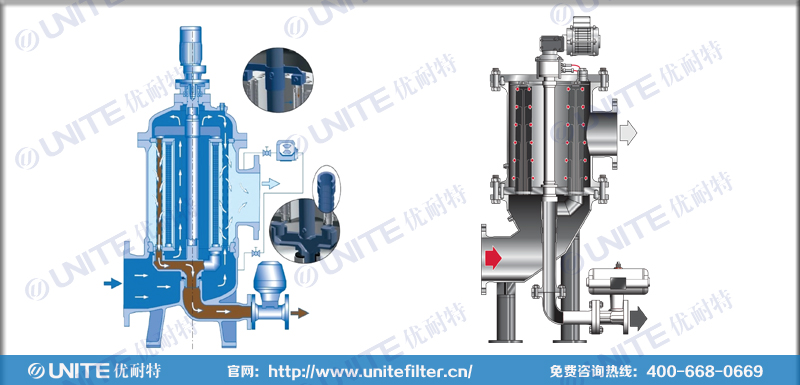

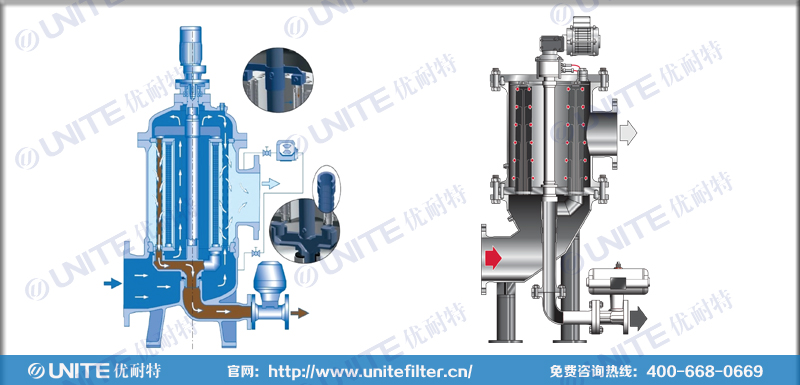

Flow mode:

6. The control system of the filtration equipment is sensitive and runs accurately. It can flexibly adjust the backflushing pressure difference and time setting value according to different water sources and filtration accuracy;

7. During the backwashing process of the filter equipment, each group of filter screens shall be backwashed in turn to ensure the safety and high efficiency of the filter screen, while other filter screens shall not be affected and continue to be filtered;

8. The filter equipment adopts pneumatic blowdown valve, with short backwashing time, less backwashing water consumption and environmental protection economy;

Filter picture:

9. Filter equipment has few vulnerable parts, no consumables, low operation and maintenance costs, and simple operation and management;

10. The working status of the filter equipment is displayed by the touch screen, and the differential pressure and time settings are convenient and intuitive.

Application fields:

1. Seawater desalination; 2. Oilfield reinjection water; 3. Boiler reuse; 4. Ion exchange pretreatment; 5. Circulating cooling water; 6. Marine ballast water; 7. Ultrafiltration and reverse osmosis pre filtration; 8. Paper nozzle filtration.

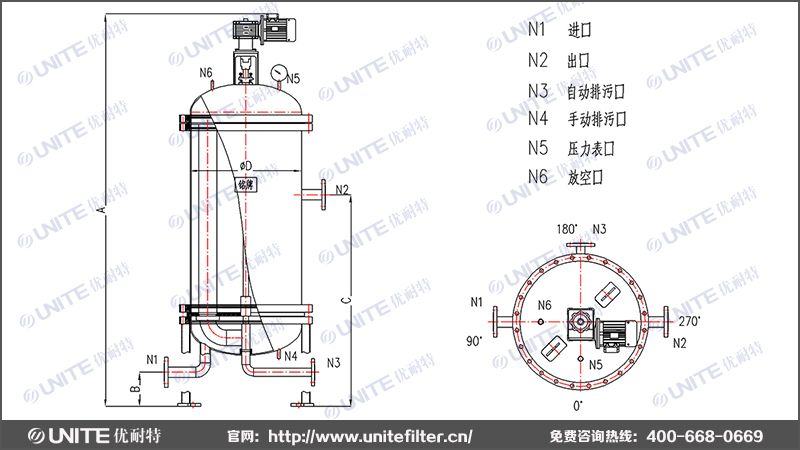

| 产品型号 | 滤芯数量 | 滤芯规格 | A(mm) | B(mm) | C(mm) | D(mm) | 进出口径 | 排污口尺寸(mm) | 参考流量(m3/h) |

| ZC-XD1-100 | 8 | φ57*650 | 1350 | 265 | 905 | 300 | DN100 | DN50 | 70 |

| ZC-XD1-150 | 12 | φ57*650 | 1420 | 265 | 945 | 400 | DN150 | DN50 | 150 |

| ZC-XD1-200 | 22 | φ57*650 | 1520 | 290 | 1000 | 500 | DN200 | DN65 | 250 |

| ZC-XD1-250 | 30 | φ57*650 | 1600 | 290 | 1050 | 600 | DN250 | DN65 | 300 |

| ZC-XD1-300 | 26 | φ80*650 | 1700 | 335 | 1050 | 700 | DN300 | DN80 | 550 |

| ZC-XD1-350 | 38 | φ80*650 | 1800 | 335 | 1050 | 800 | DN350 | DN80 | 800 |

| ZC-XD1-400 | 50 | φ80*800 | 2200 | 335 | 1150 | 1000 | DN400 | DN80 | 1200 |

| ZC-XD1-500 | 76 | φ80*800 | 2400 | 365 | 1200 | 2000 | DN500 | DN80 | 1800 |

unite@unitefilter.com

unite@unitefilter.com No. 24 all the way,industrial park,new area,Wuxi

No. 24 all the way,industrial park,new area,Wuxi  0510-85956566 400-668-0669

0510-85956566 400-668-0669