- Product Description

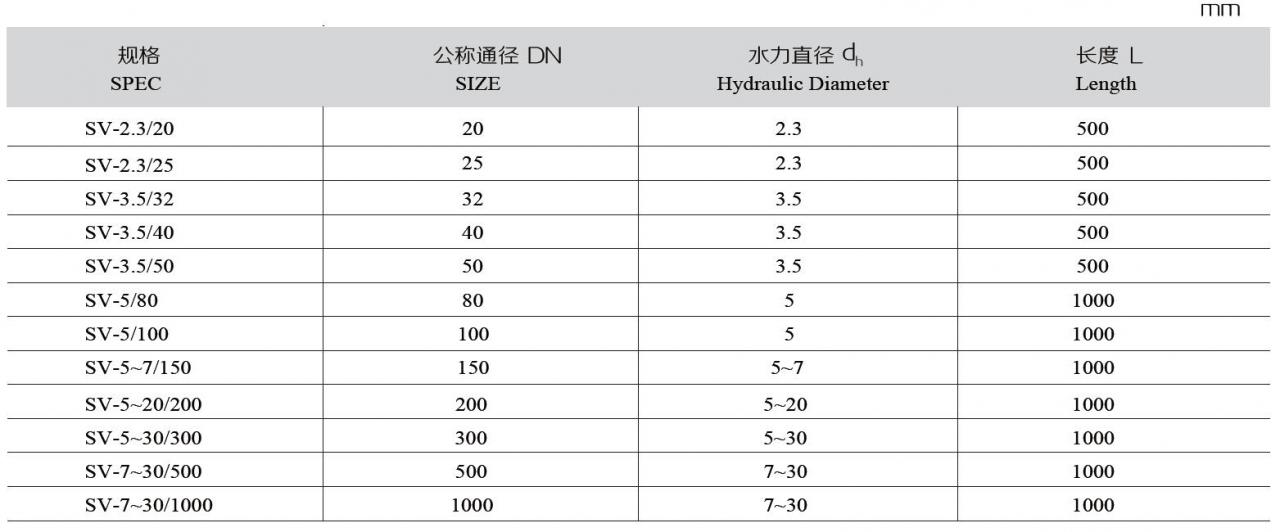

- Design Parameters

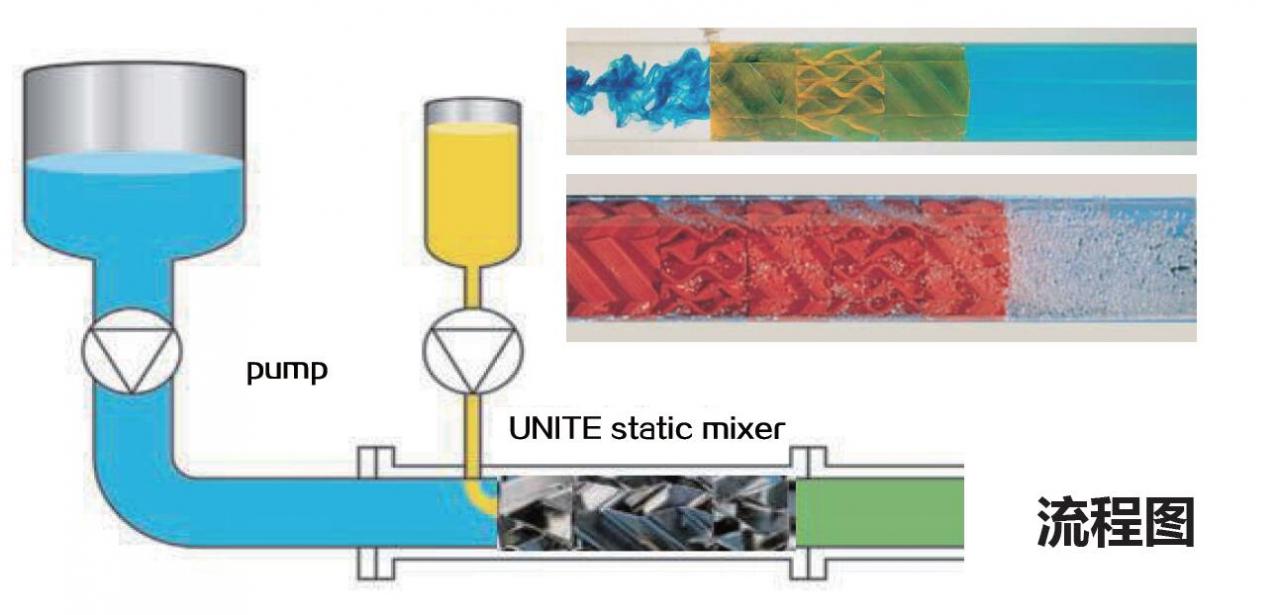

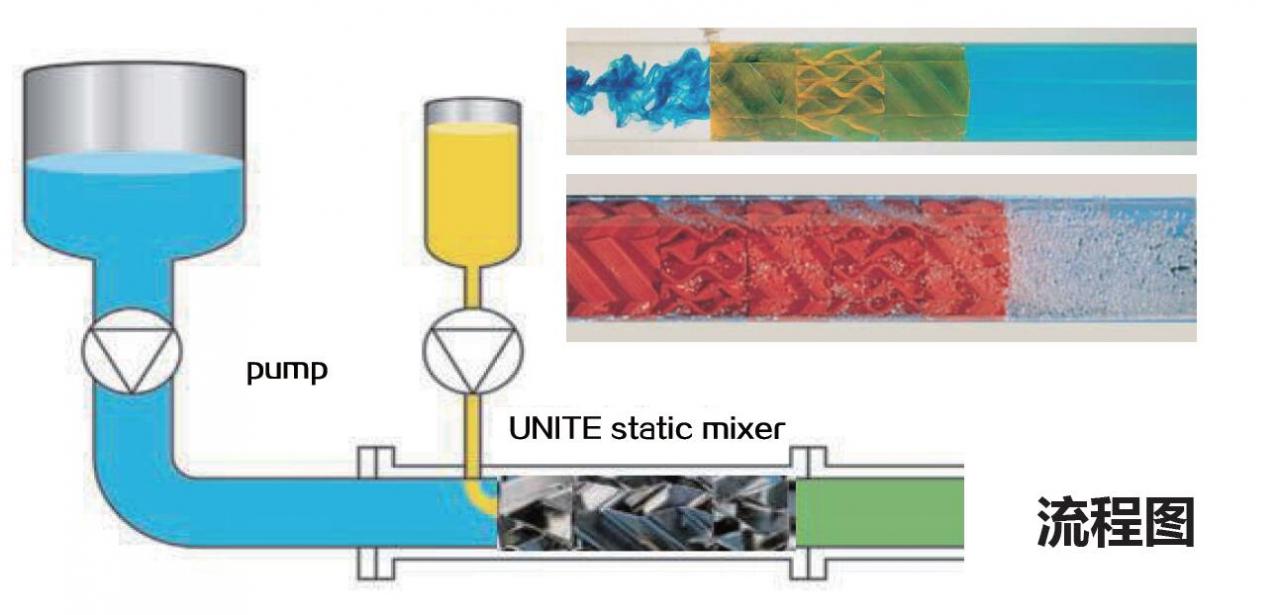

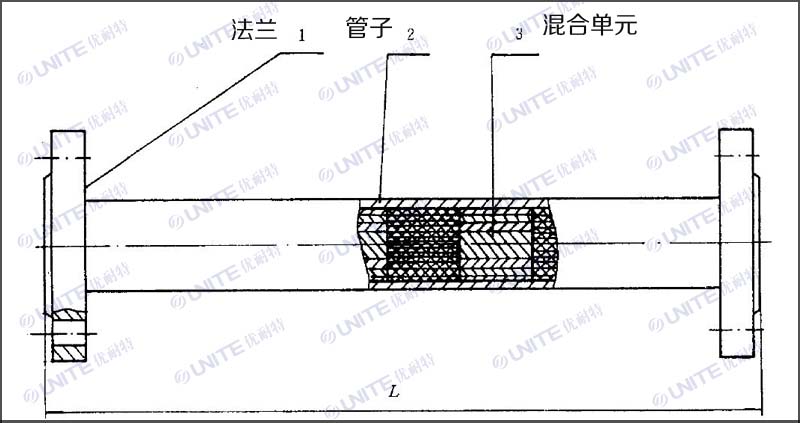

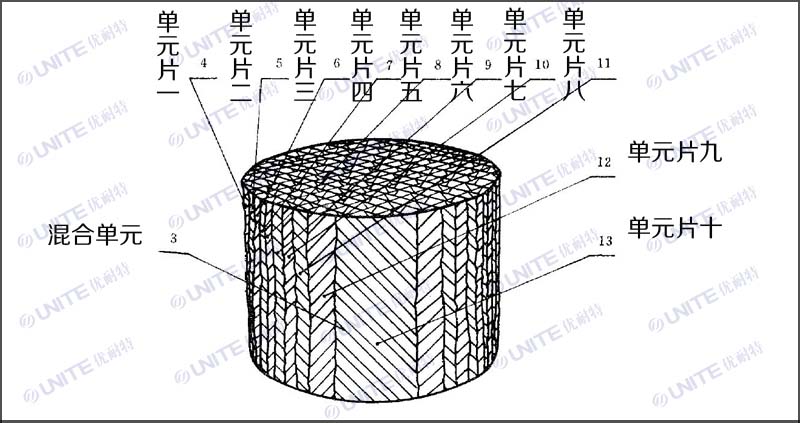

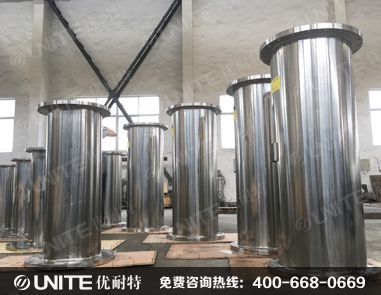

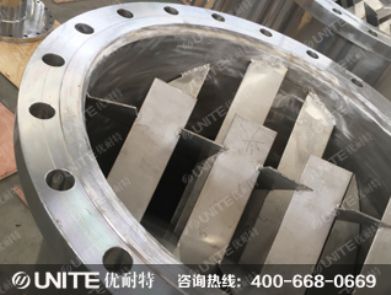

The static mixer unit of unisv is a cylinder made of corrugated plates of certain specifications. It has no moving parts. Depending on the special structure and fluid movement of the unit, the immiscible fluids are dispersed and mixed with each other to achieve good mixing effect.

working principle:

The mixing process of SV static mixer is carried out by the mixing element fixed in the tube. Due to the function of the mixing element, the fluid rotates from left to right, constantly changing the flow direction, not only pushing the central liquid flow to the periphery, but also pushing the peripheral fluid to the center, resulting in good radial mixing effect. In the same way, the rotation of the fluid itself will also occur at the interface between adjacent components. The perfect mixing effect of radial circulation makes the temperature gradient, velocity gradient and mass gradient of the fluid on the pipe cross section decrease obviously.

working principle:

The mixing process of SV static mixer is carried out by the mixing element fixed in the tube. Due to the function of the mixing element, the fluid rotates from left to right, constantly changing the flow direction, not only pushing the central liquid flow to the periphery, but also pushing the peripheral fluid to the center, resulting in good radial mixing effect. In the same way, the rotation of the fluid itself will also occur at the interface between adjacent components. The perfect mixing effect of radial circulation makes the temperature gradient, velocity gradient and mass gradient of the fluid on the pipe cross section decrease obviously.

Product features:

The product itself has no moving parts, depending on the special structure of the unit and fluid movement, so that the immiscible fluids are dispersed and mixed with each other, achieving good mixing effect.

SV type element is a cylinder assembled by corrugated plates of certain specifications. Its technical characteristics are as follows: the maximum dispersion is 1-2 μ m, the liquid-liquid phase heterogeneity is ≤ 1-5%, and the pressure drop calculation of the product is based on the diameter of water, and the influence of void ratio and friction coefficient is considered. △P=f w2 Reε=dhρc

Product use:

It is suitable for the mixed emulsification, reaction, absorption, extraction and heat transfer enhancement of liquid-liquid, liquid-gas and gas-gas with viscosity ≤ 102 centipoise. DH ≤ 3.5 is suitable for clean media with viscosity ≤ 102 centipoise, while DN ≥ 5 can be accompanied by a small amount of non stick impurities.

However, due to the small hydraulic diameter, the corresponding resistance drop Δ P is also large. To increase the treatment capacity, in addition to increasing the nominal diameter, the required power is also large. Dynamic viscosity conversion: 1p = 0.1pA · s, 1p = 0.001 PA · s

Product features:

The product itself has no moving parts, depending on the special structure of the unit and fluid movement, so that the immiscible fluids are dispersed and mixed with each other, achieving good mixing effect.

SV type element is a cylinder assembled by corrugated plates of certain specifications. Its technical characteristics are as follows: the maximum dispersion is 1-2 μ m, the liquid-liquid phase heterogeneity is ≤ 1-5%, and the pressure drop calculation of the product is based on the diameter of water, and the influence of void ratio and friction coefficient is considered. △P=f w2 Reε=dhρc

Product use:

It is suitable for the mixed emulsification, reaction, absorption, extraction and heat transfer enhancement of liquid-liquid, liquid-gas and gas-gas with viscosity ≤ 102 centipoise. DH ≤ 3.5 is suitable for clean media with viscosity ≤ 102 centipoise, while DN ≥ 5 can be accompanied by a small amount of non stick impurities.

However, due to the small hydraulic diameter, the corresponding resistance drop Δ P is also large. To increase the treatment capacity, in addition to increasing the nominal diameter, the required power is also large. Dynamic viscosity conversion: 1p = 0.1pA · s, 1p = 0.001 PA · s

working principle:

The mixing process of SV static mixer is carried out by the mixing element fixed in the tube. Due to the function of the mixing element, the fluid rotates from left to right, constantly changing the flow direction, not only pushing the central liquid flow to the periphery, but also pushing the peripheral fluid to the center, resulting in good radial mixing effect. In the same way, the rotation of the fluid itself will also occur at the interface between adjacent components. The perfect mixing effect of radial circulation makes the temperature gradient, velocity gradient and mass gradient of the fluid on the pipe cross section decrease obviously.

working principle:

The mixing process of SV static mixer is carried out by the mixing element fixed in the tube. Due to the function of the mixing element, the fluid rotates from left to right, constantly changing the flow direction, not only pushing the central liquid flow to the periphery, but also pushing the peripheral fluid to the center, resulting in good radial mixing effect. In the same way, the rotation of the fluid itself will also occur at the interface between adjacent components. The perfect mixing effect of radial circulation makes the temperature gradient, velocity gradient and mass gradient of the fluid on the pipe cross section decrease obviously.

Product features:

The product itself has no moving parts, depending on the special structure of the unit and fluid movement, so that the immiscible fluids are dispersed and mixed with each other, achieving good mixing effect.

SV type element is a cylinder assembled by corrugated plates of certain specifications. Its technical characteristics are as follows: the maximum dispersion is 1-2 μ m, the liquid-liquid phase heterogeneity is ≤ 1-5%, and the pressure drop calculation of the product is based on the diameter of water, and the influence of void ratio and friction coefficient is considered. △P=f w2 Reε=dhρc

Product use:

It is suitable for the mixed emulsification, reaction, absorption, extraction and heat transfer enhancement of liquid-liquid, liquid-gas and gas-gas with viscosity ≤ 102 centipoise. DH ≤ 3.5 is suitable for clean media with viscosity ≤ 102 centipoise, while DN ≥ 5 can be accompanied by a small amount of non stick impurities.

However, due to the small hydraulic diameter, the corresponding resistance drop Δ P is also large. To increase the treatment capacity, in addition to increasing the nominal diameter, the required power is also large. Dynamic viscosity conversion: 1p = 0.1pA · s, 1p = 0.001 PA · s

Product features:

The product itself has no moving parts, depending on the special structure of the unit and fluid movement, so that the immiscible fluids are dispersed and mixed with each other, achieving good mixing effect.

SV type element is a cylinder assembled by corrugated plates of certain specifications. Its technical characteristics are as follows: the maximum dispersion is 1-2 μ m, the liquid-liquid phase heterogeneity is ≤ 1-5%, and the pressure drop calculation of the product is based on the diameter of water, and the influence of void ratio and friction coefficient is considered. △P=f w2 Reε=dhρc

Product use:

It is suitable for the mixed emulsification, reaction, absorption, extraction and heat transfer enhancement of liquid-liquid, liquid-gas and gas-gas with viscosity ≤ 102 centipoise. DH ≤ 3.5 is suitable for clean media with viscosity ≤ 102 centipoise, while DN ≥ 5 can be accompanied by a small amount of non stick impurities.

However, due to the small hydraulic diameter, the corresponding resistance drop Δ P is also large. To increase the treatment capacity, in addition to increasing the nominal diameter, the required power is also large. Dynamic viscosity conversion: 1p = 0.1pA · s, 1p = 0.001 PA · s

Stereogram of SV static mixer unit:

Stereogram of SV static mixer unit:

unite@unitefilter.com

unite@unitefilter.com No. 24 all the way,industrial park,new area,Wuxi

No. 24 all the way,industrial park,new area,Wuxi  0510-85956566 400-668-0669

0510-85956566 400-668-0669