In the fields of petroleum and fine chemical industry, it is a very complex problem that the emulsified water in oil and process liquid can not be separated effectively. It can cause unqualified product quality, poisoning of downstream reaction catalyst, corrosion of other downstream facilities, increase operation and maintenance costs, etc.

It is difficult to separate the emulsified water depending on the physical properties of the two liquid phases. The specific gravity, viscosity and interfacial tension of the two liquids are the main parameters that determine the difficulty of separating the two liquids. When the interfacial tension is lower than 20dyne / cm, the traditional coalescing filter begins to fail. The coalescing separators of various types of high efficiency coalescing filter materials provided by our company ensure that they can be used in any liquid / liquid (oil / water) separation application process in the fields of petroleum, gas and chemical industry.

working principle:

The material enters into the pre filter from the inlet and is filtered by the filter element. The solid particles are intercepted and left on the surface of the filter element. The clean material enters the coalescing separator along the pipeline from the outlet.

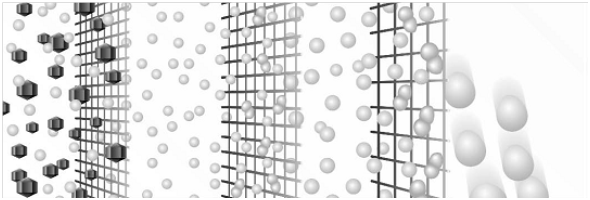

After the oil flows into the coalescing separator, it first flows through the coalescing filter element, which filters out the solid impurities and gathers the tiny water drops into larger water drops. Most of the agglomerated water droplets can be separated from the oil by self weight and settled in the water collecting tank. Then the oil flows through the separation filter element. Because the separation filter element has good hydrophobicity and lipophilicity, the water is further separated. Finally, the clean and anhydrous oil flows out of the coalescing separator. The oil enters the lower part of the filter shell through the inlet pipe, and then flows through the filter element from the outside to the inside. At this time, the coarser particles will immediately settle down and be discharged by the drain valve, and the smaller particles will be intercepted by the filter element. Finally, after the clean oil is collected by the filter tray, it flows out of the coalescer separator through the outlet pipe. With the increase of the treated oil volume, the pollutants deposited on the filter element will cause the rise of the pressure difference of the coalescer. When the pressure difference rises to 0.15Mpa, it means that the coalescing filter element has been blocked and should be replaced. The oil flows into the primary tray from the oil inlet of coalescer separator, and then flows into the primary filter element. After filtration, demulsification, growth and coalescence of water molecules, impurities are trapped in the primary filter element, and the coalesced water drops settle in the settling tank. The oil enters the secondary filter core from the outside to the inside, and then flows out of the secondary tray from the outlet of coalescer separator. The material of the secondary filter element is hydrophobic and the oil can pass through smoothly. The free water is blocked outside the filter element and flows into the sedimentation tank and discharged through the drain valve.

Oil water separation screen:

1. It is made of high-quality stainless steel mesh.

2. Its function is to separate the water and oil in the oil, with little resistance to the oil, allowing the oil to pass smoothly, great resistance to the water, and 10kg pressure water can not pass, so it plays the role of oil-water separation;

3. The technology is developed by introducing advanced filtration technology from abroad and advanced technology from our company, with various chemical components;

4. It is widely used in the filtration industry, and can play a role of oil-water separation in various fuel, aviation kerosene, diesel, gasoline, lubricating oil, hydraulic oil and other pipeline systems. It can automatically drain the water, and the oil can pass through smoothly, and can remove the free water in the oil < 10 ppm. The oil-water separation screen has a temperature resistance of 260 ° C, acid resistance concentration of 86%, alkali resistance of 90%. Jiangsu union special production, development of various models of oil-water separator, users can order according to the purpose, customized oil-water separation screen.

Filter characteristics:

1. The filter paper with multi-layer composite structure has high filtering accuracy;

2. Large capacity and long service life;

3. Large flow density reduces the size of fine filter;

4. Carefully set and specially treated glass fiber layer has good coalescence effect.

5. Complete specifications and varieties can meet the needs of various fine filters.

unite@unitefilter.com

unite@unitefilter.com No. 24 all the way,industrial park,new area,Wuxi

No. 24 all the way,industrial park,new area,Wuxi  0510-85956566 400-668-0669

0510-85956566 400-668-0669